(!) This solution was replaced by Sivacon S8. The spare parts for equipment delivered in the past are still provided.

In 2002 Automatica undertook the license to produce in Romania the Sivacon electric switchboard series and became SIEMENS’s Sivacon technology partner.

SIVACON is a type-tested (TTA) command and distribution switchboard system, whose technical characteristics are tested in the laboratory both for normal operating conditions as well as for fault situations.

The relevant type tests insure a maximum operating performance and safety. SIVACON complied with the testing requirements detailed in IEC 60439-1, of EN 60439-1(VDE0660 part 500).

| Standards and specifications | Normal operating conditions |

IEC 60436-1 |

|

IEC 60439-1 |

||

|

VDE 0660 PART 500 |

||

| Faults situations |

IEC 61641 |

|

|

VDE 0660 PART 500, suppl. 2 |

||

| Creepage distances and clearances | Rated impulse withstand voltage Uimp |

8 kV |

| Overvoltage category |

III |

|

| Pollution degree |

3 |

|

| Temperature |

|

≤ 50OC |

| Rated frequency |

|

50 Hz |

| Rated operational voltage |

Ue |

Max. 690 V |

| Rated insulation voltage |

Ui |

1000 V |

| Peak withstand current |

|

Max. 375 kA |

| Short-time withstand current |

|

Max. 150 kA, 1 s. |

| Protection degree |

According to IEC 60529 |

IP 30 to IP 42 with natural ventilation |

| IP 54 without natural ventilation | ||

| Internal separation |

Form 1 to form 4 |

Acc. to IEC 60439-1 part 7.7 |

| Metallic construction |

Frame |

Zinc-coated steel sheet 2,5 mm thick |

|

Enclosure and door |

Steel sheet 2 mm thick, powder coated, in electric field, in standard grey color RAL 7032 | |

| Dimensions | Height: 2200, 2600 mm

Width:600, 800, 1000, 1200 mm Depth: 600, 800, 1000, 1200 mm |

The SIVACON switchboard is made exclusively of standardized and type-coded modules.

All the modules are high quality and conform to SIEMENS’ design specifications.

The multiple possibilities of combining the components fulfill every requirement.

The low voltage distribution and command switchboards insure:

- Power distribution at the levels of power center, main distribution board or sub-distribution board (FCB,BC);

- Cable feeders equipped with circuit-breakers or fuse-switch-disconnectors (conventional or in-line)(OFF, OFPD);

- Motor control centers (MCC) in “plug-in“ (OFPM) or withdrawable (OFW) design;

- Automatic central reactive power compensation (PFC).

The supply, feeder and coupling cubicles of the circuit-breaker are equipped with automated type 3 WL circuit-breakers in withdrawable or fixed-mounted execution.

Due to the large number of consumers (loads) connected, a particular importance is given to ensuring a long-term operation in conditions of performance, reliability and safety for the operating personnel.

Cable feeders equipped with circuit-breakers or fuse-switch-disconnectors (conventional or in-line) (OFF, OFPD).

The cubicles (OFF) for cable feeders, in fixed-mounted execution are equipped with molded case circuit-breakers or fuse-switch-disconnectors (conventional or in-line).

The compartment design with its individual sub-section for every circuit-breaker offers increased active safety both for installation and personnel protection.

The cubicles are used in applications in which the replacement of devices during operation is not necessary or when short downtimes are accepted.

The “plug-in” (OFPD) design, in-line, offers a more economically advantageous solution to the “withdrawable” unit design.

The modules are easily interchangeable without switchboard shutdown, thanks to the supply-side plug-in contact and their compact design.

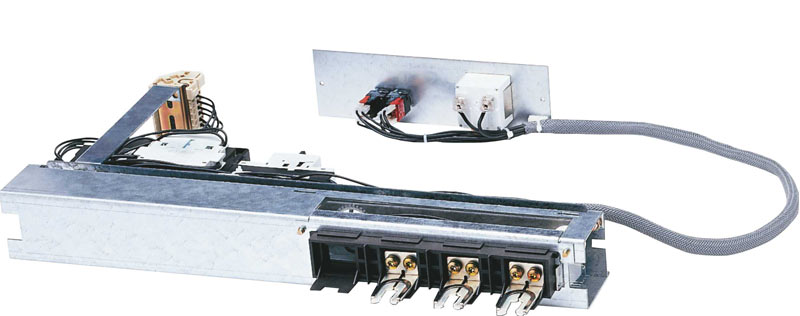

The low voltage SIVACON switchboard in “plug-in” (OFPM) design is an efficient standard solution for motor control centers (MCC).

This design offers obvious advantages compared to the classical design and is destined to be used mainly in the chemical industry, waste treatment stations, water supply stations, etc.

The low voltage SIVACON switchboard in withdrawable (OFW) design represents an extremely accesible standard solution for motor control centers (MCC).

The OFW design offers a high degree of flexibility, safety in operation and availability as well as continuous power supply in the industrial processes.

Thanks to the withdrawable construction quick changes and adaptations during operation are possible.

Construction specifications:

- Standard configuration in 8 module heights (100, 150, 200, 300, 400, 500, 600, 700 mm);

- Coupling for auxiliary circuits with up to 40 poles;

- Frontal panel with hinges of the withdrawable unit (modules with height > 200 mm);

- Coupling mechanism for the easy movement of the withdrawable units > 250 A;

- Large space for the auxiliary equipment thanks to the possibility to install components on the back side;

- The withdrawn position can be locked to the purpose of maintaining the safety operation at the consumer.

Automatic central reactive power compensation (PFC)

The switchboards for the automatic central reactive power compensation decreases the overload of the transformers and cables, reduces the power losses and the energy costs.

Based on the load structure, they can be equipped with capacitor modules with or without smoothing chokes.

Controller module with electronic power factor controller for flush door mounting:

- Multifunction display,

- Self-adaptation of the value C/K,

- Adjustable nominal cos Φ from 0.8 inductive to 0.98 capacitive,

- Manual or automatic operation.