The automatic belt weigh-feeders are used in any industrial process requiring a constant afflux of material (granular or powder) with a constant mass flow. The belt conveyor includes a weighing system for the material on the feeder-belt.

The equipment allows communication with a computer or PLC and it is produced by Mitsubishi Electric, characterized by the following performances:

- Special flexibility in the configuration of any application,

- Easy integration in the industrial communication networks (Ethernet, Profibus, DeviceNet, RS 485, CC-Link, Can Open),

- Initial low cost of the equipment,

- Low maintenance cost, the spare parts being produced in large series,

- Compatibility with CE industrial standards, guaranteed through certification.

| Technical data | |

| Batching accuracy | ± 0.25% … ± 1% |

| Belt widths | 500, 650, 800, 1000, 1200, 1400, 1600, 1800 mm |

| Rated flow | 0,1…….1000 t/h |

| Flow prescription range | 1% … 100% from normal flow |

| Electronic equipment | FX3G/FX3U Mitsubishi Electric |

| Power supply voltage | 220/380 V ±10% |

| Rated frequency | 50 Hz ± 2% |

| Max. consumption power | 0.5 – 10 kVA |

| Protection degree | Central electronic equipment: IP 65

Local electronic equipment: IP66 Proximity detectors: IP67 Load cell: IP68 |

| Operating conditions | |

| Mounting place | Indoor, outdoor |

| Climatic protection | Temperate, tropical |

Ambient temperature

|

-100C … +550C -250C … +700C -250C … +700C |

| Relative humidity at 200C | 65% ± 20% |

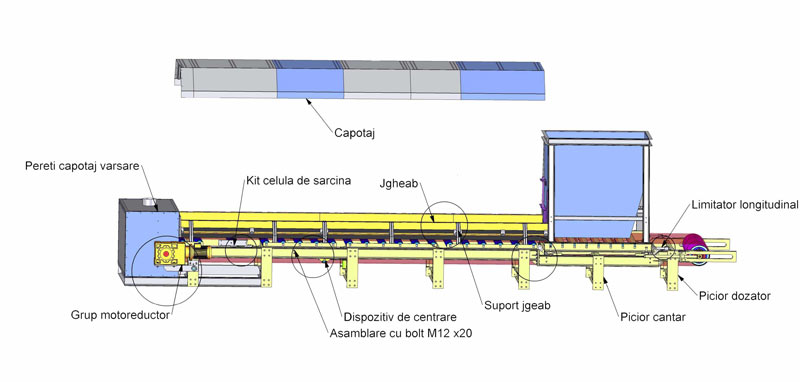

The automated belt weigh-feeder BWF-201M produced by Automatica SA is the result of over 30 years of experience in the field of gravimetric weigh-feeding systems. The continuous evolution in this field of major importance for the heavy industry was carefully followed and it determined the addition of new solutions that would offer superior performances and a continuous decrease of the price per application.