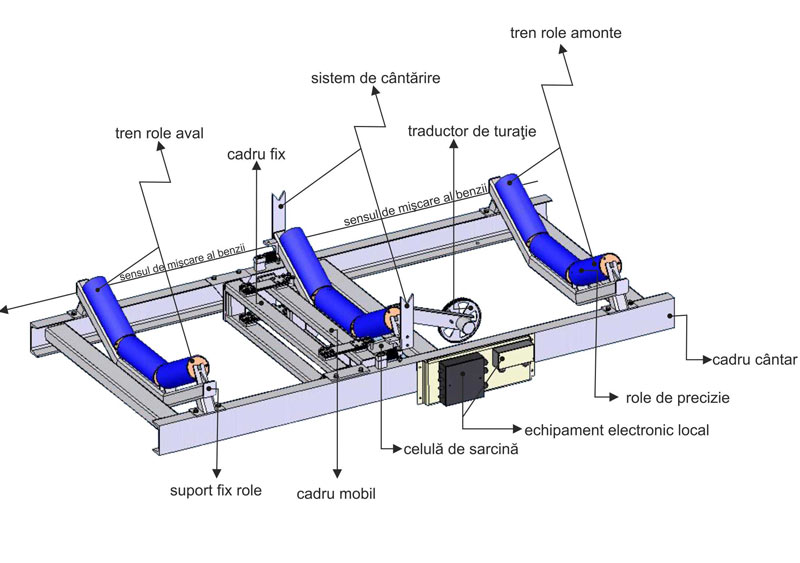

The electronic belt-weighers produced by Automatica SA are designed for the high precision weighing of the materials conveyed on fixed or variable speed conveyor belts.

The operating principle is based on the dynamic weighing with software fragmented and indexed belt that offers the highest achievable precision in industrial applications, in difficult operating conditions.

The weighing is not influenced by the variations in thickness, width or density of the conveyor belt.

The belt-weighers are equipped with operator consoles that insure the visualization of the operating parameters and the entering of the calibration and configuration parameters.

For the essential parameters of the belt-weigher (debit, specific load and belt speed) evolution trends are posted that are very useful in supervising the process evolution.

| Technical data | ||

| Flow range | 0,5….4000 t/h | |

| Weighing precision | ±1%; ±0,5%; ±0,25% complying with the OIML-R50 conditions | |

| Belt width | 500, 650, 800, 1000, 120, 1400, 1600, 1800, 2000 mm | |

| Weighbridge length | 0,8 – 5 m | |

| Cell used | UTILCELL | |

| Electronic equipment | FX3G/FX3U Mitsubishi Electric | |

| Power supply voltage | 110…264 V c.a. | |

| Rated frequency | 50 Hz ± 2 Hz | |

| Maximum consumption power | 0,075 kVA | |

| Protection degree | Central electronic equipment: IP65

Local electronic equipment: IP66 Proximity detectors: IP67 Load cell: IP68 |

|

| Operating conditions | ||

| Mounting place | Indoor, outdoor* | |

| Climatic protection | Temperate, tropical | |

Ambient temperature

|

-10OC…+55OC -25OC…+70OC -25OC…+70OC |

|

| Maximum altitude | 2000 m | |

*the indoor mounting is allowed if the influence of the environment factors does not affect the weighing precision (wind, moisture, deposits).